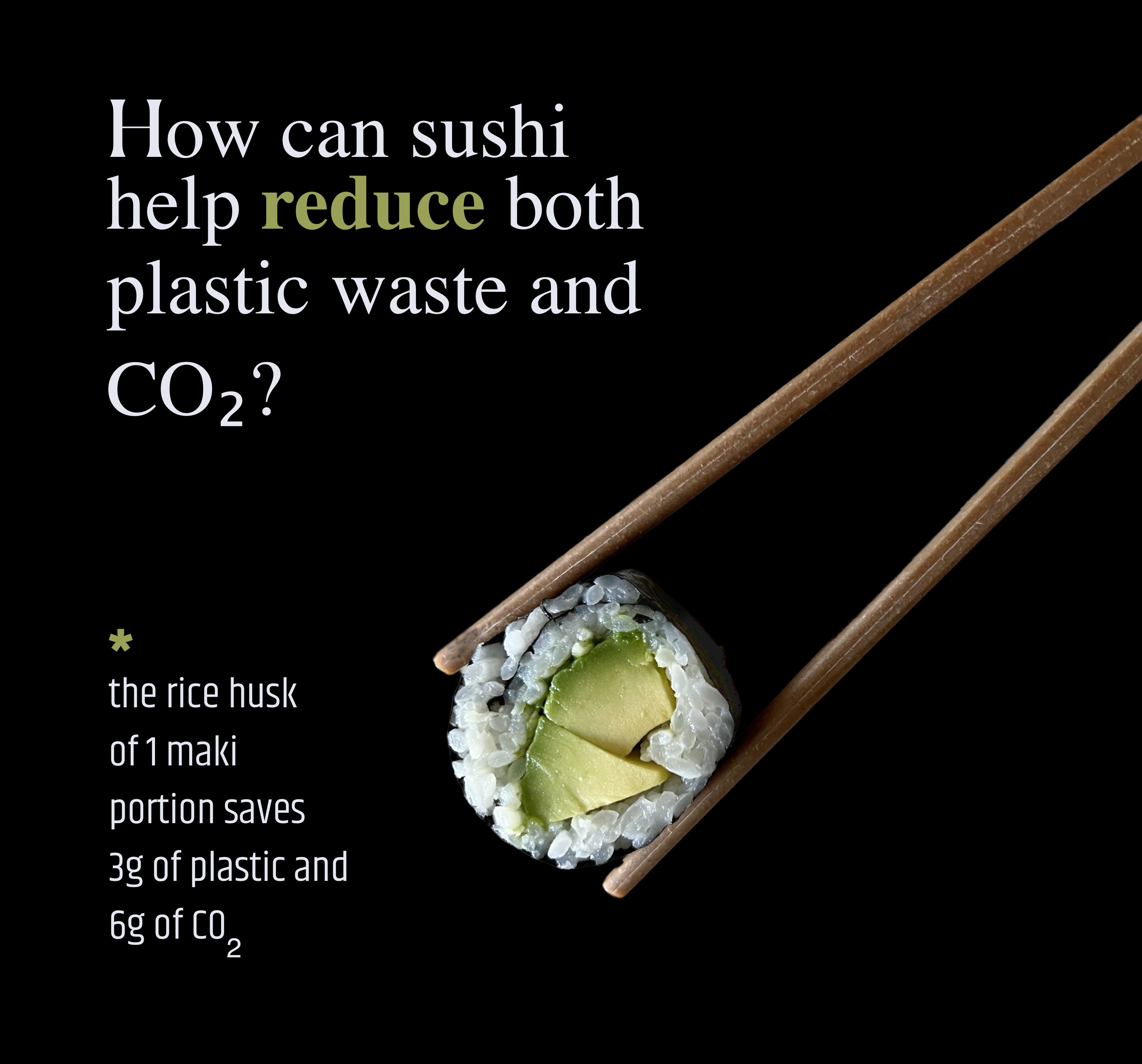

Introducing Oryzite

a patented system to replace plastic

It is a globally patented method for incorporating rice husk into all types of polymers and the use of plastics can be

reduced by up to 85% !

For more than 15 years our team of researchers have studied the behavior of plastics by adding waste component such as rice husk and the results have been more than surprising.

Oryzite is a material made from rice husk. An enzymatic process, also coming from the rice plant, turns it into a powdered natural filler.

WEIGHT

COST EFFICIENCIES

PROPERTIES

This transformation gives a second life to this agro product waste, since this material can be added to all kinds of thermoplastic compounds in different percentages (in some cases up to 85.%). The final composition of Oryzite is adjusted depending on the polymer with which it is going to be mixed.

This bio-filler provides many physical advantages to plastic parts, such as better mechanical properties, dimensional stability or flame retarding. In addition, Oryzite also enables weight and raw material cost efficiencies, hand in hand with a reduction of the final part production cycle.

HAVE A LOOK AT ALL OUR PRODUCTS

RYZ-100 powder bio-filler for polymers with melting point up to 220 ºC

RYZ-200 powdered bio-filler for polymers with melting points above 220 ºC

RYZ-500* powdered bio-filler for polymers with melting points up to 220 ºC

*prepared for low-odor packaging

ABOUT CO2

For every kilogram of fossil-based plastic produced there is between 1, 7 and 3, 5 kilograms of carbon dioxide released.

With a possible worldwide Oryzite production

of 150 million tone yearly…

DO THE MATH !

Made by nature, manufactured by Oryzite

In the manufacturing process of Oryzite we do not use water as a resource and we obtain 16 kg of it for every kW used.

Manufacturing with Oryzite allows us to reduce CO2 emissions while saving energy because we do it at lower temperatures and with shorter cycle times.

Planet

Compatible

Sustainable, 100% biodegradable and recyclable

Oryzite is the perfect example of circular economy,

the one that uses the least resources and produces the least waste.

APPLICATIONS

Oryzite is already present in different branches of the industry.

It’s applied in civil engineering, in tiles and manhole covers; in outdoor equipment structures and enclosures; in the packaging sector, as trays, pallets or cosmetic containers; sewing notions such as buttons or buckles, bathroom accessories and the automotive industry.